Plumbing, Heating and HVAC Pumps and Other Heating Specialties

We offer a complete line of Plumbing, Heating & HVAC pumps, from small in-line circulator pumps to large, base-mounted end-suction centrifugals. We are also the experts when it comes to hard-to-find replacement parts. A heating system includes a lot more than just the pumps, of course. That’s why we carry assorted pump supplies and various accessories that you need to keep your system running. We can help diagnose heat loss issues; test steam traps; offer recommendations to save energy and efficiency.

Circulator Pumps

Circulator pumps are designed for circulation of hot water for heat transfer in hydronic heating systems, whether residential or commercial. They are generally available in a variety of materials including cast iron (most commonly for closed loop systems), bronze and stainless steel, and have capacities ranging from 3 gpm to more than 5,000 gpm. Small- to medium-sized circulator pumps are usually supported entirely by the pipe flanges that join them to the rest of the hydronic plumbing. Large pumps are usually pad-mounted.

Product styles and configurations for these types of pumps include:

- Water Lubricated Circulators

- 3-Piece Circulators

- In-Line Circulators (including models with built-in PC boards and Zoning Circulators)

- Vertical In-Line Pumps

- Close Coupled & Frame Mounted End Suction Pumps

- Horizontal Split Case Pumps

- Vertical Multi-Stage Pumps

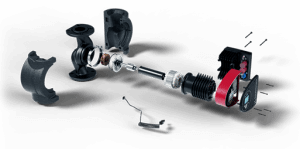

Three-Piece and Cartridge-Style Circulators

The two main pump types in most hot water recirculation applications are three-piece circulators, which require oil lubrication and have more replaceable parts, and cartridge-style circulators, which are water-lubricated and have few replaceable parts. The most common replacement part for a cartridge circulator is a new cartridge.

Our most popular brands in this product category include Taco, Bell & Gossett and Grundfos. Taco’s best seller is the 007 series; for B&G, it’s the Series 60 and 100 pumps; and for Grundfos, their signature UP pumps.

The last handful of years has brought increased emphasis in high-efficiency variable speed circulators. For instance:

- The Taco Bumble Bee is a multi-function variable speed, wet rotor circulator with an ECM, permanent magnet motor. Its high efficiency DC motor reduces power consumption by up to 85% compared to AC permanent split capacitor circulators. It’s also packed with features like an LED display and simple controls.

- For larger capacity jobs, Taco offers the versatile Viridian, which allows the operator to dial in a flow rate or choose from six pressure presets to fit the job. Like the Bumble Bee, it also features an LED display.

- B&G’s EcoCirc and EcoCirc XL, meanwhile, build on this new technology to go even further. While the EcoCirc is geared toward residential applications, the EcoCirc XL is specially made for the commercial market. With an efficient ECM motor, the EcoCirc XL can operate in three different standard control modes: (1) Proportional Pressure Control, (2) Constant Pressure Control or (3) Constant Speed. Night Mode functionality provides additional energy savings. Finally, advanced settings can be managed from a PC, tablet or smart phone, and are accessible via optional built-in wireless or RS-485 cable.

- Grundfos’ ALPHA pumps are commonly viewed as the simplest of this new class of pumps. The pump’s factory presets will automatically analyze the heating system and find the optimum setting and continue to adjust its operation to changes in demand. It has a permanent magnet motor design, and advertises comparable energy savings as the Taco Bumble Bee.

- Building on its ALPHA technology, Grundfos’ MAGNA 3 pumps includes all of the above features but offer extended ranges with maximum heads

of 60 feet and maximum flows of 550 gpm. Perhaps its most impressive features involve its communication capabilities. First, the MAGNA 3 can be easily synced with common building management systems. Additionally, each pump comes with built-in wireless communication capability to connect to other MAGNA 3 pumps, whether to operate in parallel, alternating or with one as a back-up. Finally, the Grundfos GO Remote allows intuitive control with an iPhone or Android mobile device.

of 60 feet and maximum flows of 550 gpm. Perhaps its most impressive features involve its communication capabilities. First, the MAGNA 3 can be easily synced with common building management systems. Additionally, each pump comes with built-in wireless communication capability to connect to other MAGNA 3 pumps, whether to operate in parallel, alternating or with one as a back-up. Finally, the Grundfos GO Remote allows intuitive control with an iPhone or Android mobile device.

Circulator Pump Replacement Parts

We offer the widest selection of spare parts for heating pumps. Ask us about Woods/Lovejoy Sure-Flex Couplers and Sleeves, which fit all m manufacturers’ pumps; replacement cartridges; couplers; gaskets, in smooth red and black ring style; bolts and gaskets; and flanges. Did you know that B&G’s HV flanges fit all other manufacturers’ circulators?

manufacturers’ pumps; replacement cartridges; couplers; gaskets, in smooth red and black ring style; bolts and gaskets; and flanges. Did you know that B&G’s HV flanges fit all other manufacturers’ circulators?

Whatever the pump, whatever the part–Duff’s pump specialists are the leaders in the field in helping you identify that hard-to-find item. Our team has been doing this longer than just about anyone in the business, so just give us a try: The Parts Guru is waiting for your questions.

End Suction Pumps

We can help you with repair parts on many different kinds of pumps used in heating applications, including floor-mounted end suction pumps with foot supported volutes in several designs. We offer pumps and replacement parts from the leading manufacturers:

- B&G

- PACO Pumps

- Peerless Pumps

- Berkeley

- Aurora

- Thrush

Pressure Vessels

We also offer pressure vessels (ASME or non-ASME) in composite material and stainless steel from the leading manufacturers, including Taco, B&G, John Wood, Wesels, Amtrol and others.

ASME Code pressure vessels are designed and manufactured in accordance with Section VIII, Div. 1 of the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code. The ASME Code controls the pressure vessel design, materials used, welder qualifications, methods of construction, inspections and documentation. Code vessels are produced with a 3.5:1 safety factor, follow a strict quality control program, and are reviewed by a third party authorized inspection agency. Fittings for Code vessels are typically 3,000 pound designs or ANSI flanges. Following construction, each vessel is hydrostatically tested to 130% of its design pressure.

Non-Code pressure vessels are designed and manufactured with similar guidelines, in the same facilities and by the same experienced people as ASME Code vessels. Non-Code vessel designs use a lower, but still conservative 3:1 safety factor and can use a broader range of materials. Fittings used for non-Code tanks are typically 150 pound designs or ANSI flanges. You can expect non-Code vessels to cost much less than ASME vessels, for obvious reasons.

Many schools and government buildings require vessels be ASME certified, so it’s important to let us know whether you have this requirement.

Valves & Accessories

Our staff is trained in the nuances of heating systems, able to address even the most difficult questions on boilers, trim, zoning, and related accessories.

Zone Valves & Transformers

Many of the zone valves out today are much more efficient than they were even 10-15 years ago. Some use up to 95% less energy than the last generation of zone valves did. Some include the ability to connect up to 12 valves on a single 40 VA transformer; have multi-function LED screens to assist in trouble-shooting; offer bidirectional flow (so you can’t install the valve backwards!); and quick-release actuator mounting.

Pilot-Operated Regulating Valves

These regulators are more accurate and offer higher capacities than standard direct-operated regulators. They maintain constant set outlet pressure, even  when inlet pressure fluctuates or variations in flow occur. With the proper selection of pilots, these regulators will accurately control temperature, pressure or a combination of both.

when inlet pressure fluctuates or variations in flow occur. With the proper selection of pilots, these regulators will accurately control temperature, pressure or a combination of both.

The Watson McDaniel HD Series Pilot-Operated Regulating Valve, as an example, features a ductile iron body for increased pressure and temperature ratings. It is ruggedly designed for steam service and can be configured with a variety of pilots or pilot combinations, giving it extreme versatility. Using the Standard “P” Pressure Pilot, outlet pressure can be reduced in the range of 3-200 PSIG, depending on the selected spring. Maximum operating pressure for the HD Regulating Valve is 300 PSIG. (The “T” Pilot is for reducing temperature, with a control range of 60-260°F. Other options include “A” Air Pilot, “DP” Differential Pressure Pilot, “BP” Back Pressure Pilot and “S” Solenoid Pilot.)

One of our specialties is finding replacement parts for regulating valves, whoever the manufacturer–Cla-Val, Watts, Spence, Emerson, Cashco, Warren, Spirax Sarco, Watson McDaniel–and whatever the part.

Direct-Operated Regulating Valves

We offer several self-contained pressure reducing valves for use with steam, water, oil and other liquids and gases. These include direct-operated pressure regulators, like the popular Watson McDaniel “O” Series Regulators, which can regulate outlet pressure in the range of 0-200 PSIG and its “B” Series Regulators, with a range of 1-125 PSIG.

The 455 Series Externally-Sensed Regulators are used for reducing pressure in steam, air and water systems (commonly in heating applications). Externally-sensed regulators are often more accurate than internally-sensed regulators because the sensing line is connected close to the process it is intending to control, yet far enough away from the outlet of the regulator to not be affected by turbulence.

Back Pressure/Relief Valves are used to maintain a specific back pressure or to protect systems from an over-pressure condition. Direct-Operated Temperature Regulators, meanwhile, can be used for accurately controlling temperatures in both heating and cooling applications. These mechanically operated valves are recommended for controlling flow on relatively stable systems, where small valve stroke modulations will control temperature drift.

Steam Traps

Steam traps are essential components of any steam system. They are used to discharge condensate, air or other non-condensable gases from a steam system while preventing the loss of steam. Steam traps are generally used in drip, process and tracing applications, and come in a variety of sizes and types to effectively handle various operating conditions. Proper selection of a steam trap is mainly dependent on the application type, condensate load and operating pressure.

We offer an extensive line of steam traps to handle virtually any application. These include Thermodynamic, Thermostatic, Float & Thermostatic (F&T), Inverted Bucket, Clean Steam and Bi-Metallic steam trap types. In addition, Manifolds are available which are used for steam distribution to tracing systems and for condensate collection.

Universal Style Steam Traps are available to simplify installation and maintenance. These traps consist of a Universal Connector and a Universal Steam Trap Module. The Universal Connector is designed to be installed into the pipeline and the Module is designed to easily connect or disconnect to the Universal Connector.

Condensate Return Pumps

Pressure Motive Pumps (PMP) are designed to transfer hot condensate (or other liquids) without the use of electrical power. The primary application for the PMP is pumping condensate from a process application or condensate collection area back to the condensate return system.

We can also help you with PMPs with receiver tanks, whether in ductile iron, cast iron or fabricated steel. The receiver tanks are generally manufactured from carbon steel.

If you have an electrical source, a better option may be an electric condensate pump, which is generally available for condensate temperatures up to 190ºF. Pump tanks are either carbon steel or cast iron. The pumps are generally bronze-fitted centrifugals with energy efficient motors and heavy-duty float switch. These types of units are offered with various options, such as in simplex or duplex packages, oversized or stainless receivers, gauge glass, thermometer, discharge pressure gauge, isolation valves, magnetic starter, mechanical or electric alternators, NEMA control panel, and high temperature (250ºF) components.

Air Elimination & Other Specialty Products

Air vents, air eliminators and air separators–call or email us to see what’s best for your application.

We offer other specialty items for steam and fluid applications including safety relief valves, vacuum breakers, freeze and scald protection valves, suction/mixing tees, wye-strainers, and flash steam recovery vessels.

You might not know that Duff also provides custom welding and fabrication services. We make-to-order specialized strainers and baskets; steam specialties, including flash tanks, quench tanks, skidded water treatment systems and equipment, and pump components; spool pieces, manifolds and headers; various custom-made receivers and tanks.

Steam/Hot Water Unit Heaters

Did you know that Duff stocks and distributes steam/hot water unit heaters? Available with top/bottom (HS) or side (HC) inlet/outlet piping, Modine unit heaters install quickly, easily and at low cost because they are lightweight. Yet they are ruggedly constructed to resist rigorous handling and on-the-job abuse.

Horizontal Unit Heaters (HS/HC)

The horizontal steam/hot water unit heater is ideal for general commercial and industrial applications. Available with top/bottom (HS) or side (HC) inlet/outlet piping.

Vertical Unit Heaters (V/VN)

Recommended for a wide range of heating requirements, vertical steam/hot water unit heaters provide downward air delivery. These units may be suspended from up to 54 feet above the floor, depending upon the heater specifications.

Power Throw Heaters (PT)

Carrying a powerful, high-velocity air delivery system ranging from 1,860 to 2,520 cubic feet per minute, these heaters are recommended to warm areas around frequently-opened doors or wherever long horizontal heat throws are required.