The Grundfos line of LC panels for emptying and filling applications is designed in one-or two-pump control. It is ideal for wastewater lifting stations, stormwater stations, commercial building and industrial sumps, drainage and tank fill applications and more.

The controller has two modes: EMPTYING or FILLING. The controller is equipped with a comprehensive range of features for complete pump station set up, monitoring, and control. Predefined settings offer fast and easy start-up, and it supports up to five control levels for analog level transmission or float switch operation.

Configurable Inputs and Outputs (CIO)

The controller has a number of free inputs and outputs for extra sensors, such as outlet pressure from the pit. The Grundfos CIO ports (Configurable Input/Output) can be configured to fit almost any type of signal, including digital input/output, analog input and Pt 100/1000 inputs. The two relay outputs can be configured using Grundfos GO to show a variety of status information on a supervisory system or PLC.

Start and stop signals are used for normal operation, and the optional dry run signal will protect the pumps from dry running.

The controller gives an alarm in the event of current overload, dry running, high water level, incorrect phase sequences or missing phase, sensor inconsistency or failure, intrusion detected, water on floor, too many restarts, or moisture in pump. The alarm and warning log maintains detailed information on the last 20 alerts, accessible remotely via SCADA or Grundfos Go for easy troubleshooting.

Easy SCADA Integration

The controller uses open protocols for connection to any SCADA system. This allows you to access your pumping stations or filling station remotely, to control the pumps, change settings and view alarms and operations data.

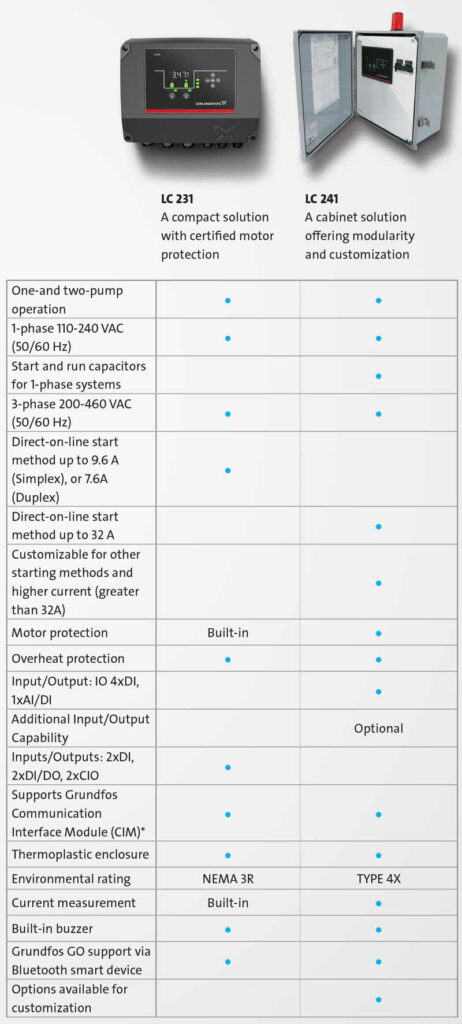

LC 231 and LC 241 Comparison

Grundfos LC panels are available in two variants:

LC 231 – a compact solution with certified motor protection

LC 241 – a modular panel with a dead front offering options for customization

Additional LC 231 and LC 241 Features:

- Anti-seizing

- Max numbers of restarts

- Pump statistics and maintenance indicators

- PIN code security and protection

- Historical functional data log

User-Friendly Interface

Save valuable time with the intuitive and easy-to-use interface. The LC control system is equipped with configurable input/output terminals, offering flexibility for all applications. Daily

control, supervision and commissioning is simple and straightforward.

Additionally, the controller is able to integrate into Supervisory Control and Data Acquisition (SCADA) systems.

Mobile Configuration

Set up and configure your LC controller through the Grundfos GO mobile app. Using Bluetooth technology, Grundfos controllers offer easy and seamless integration so you don’t have to be on site to connect, monitor or manage your pump station.

The simple and intuitive dashboard displays your installation status where you can monitor the pit and pumps at a glance. View priority areas faster with shortcuts to alarms and warnings, manual pump control and a detailed pump status.

You can also generate a complete report that shows the settings and status of the installation.

Optional features such as anti-seizing or power-on delay can be adjusted. Grundfos GO can also be used to store the complete settings for your pumping station or copy the settings for future installations.