High-pressure washdown systems are vital to food processing plants and manufacturers. But durability, efficient operation, and cost-effective maintenance are hard to obtain. Pitot tube and positive displacement pumping are things of the past. The Grundfos Hydro HP is a better way to run a washdown system. It offers full ROI in just a few maintenance cycles.

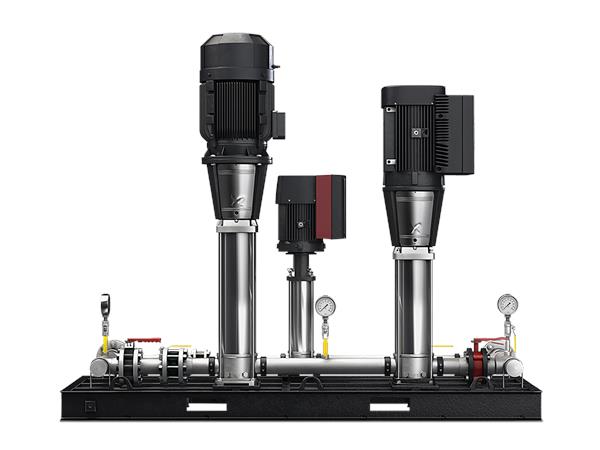

This high-pressure boosting system offers more reliable and energy-efficient washing and cleaning. With industry-leading CR vertical multi-stage inline pumps, the Hydro HP offers bulletproof reliability and superior hydraulic performance in a space-saving footprint, and the integrated VFD control offers consistent system pressure.

Whether you require one spray wand to clean or need a full facility washdown, this pump does it all without recirculation lines. An integrated VFD control and low-flow jockey pump maintain consistent system pressure to meet low-flow cleaning demands.

And, with the easily serviced Grundfos Hydro HP, plants can expect to realize full ROI after the first few maintenance cycles.

Efficient Design

The Hydro HP uses minimal energy—unlike pitot tube pumps which run constantly to meet high pressure needs. With cascade control, integrated VFDs, and pump design, the Grundfos Hydro HP dramatically reduces energy use without sacrificing performance.

- No recirculation line needed for consistent pressure

- Integrated variable frequency drive adapts to system demands

- Vertical multistage pumps designed for maximum efficiency

Reliable Engineering

Built to minimize wear — unlike pitot tube pumps, which push water through a small opening at a high velocity, causing faster deterioration. This industry-leading boosting system is engineered with reimagined features to increase reliability and decrease downtime.

- Lower vibration minimizes wear and tear

- State-of-the-art testing before leaving the factory

- Single-source responsibility, with all parts designed to work together

Easy Maintenance

Most maintenance can be done in-house when needs arise — unlike pitot tube pumps, which can require frequent and costly off-site servicing.

- Shaft seal can be replaced in minutes without removing the motor

- Rotating assembly stacking kit allows for easy replacement

- No need to realign or rebalance the pump